Unlocking the Backbone of Plastic Sheet Manufacturing

In the rapidly evolving landscape of plastic production, the PET sheet making machine has become a linchpin for manufacturers seeking high efficiency, precision, and environmental responsibility. For companies that work with materials like PET, PP, and PLA, choosing the right equipment isn’t just about output—it’s about optimizing quality, sustainability, and long-term value.

At the heart of this transformation is Guangdong SIVITE Intelligent Manufacturing Co., Ltd., a company born in 2010 in Dongguan, famously known as the "World Factory." With a track record of innovation, quality assurance, and customer satisfaction, SIVITE’s solutions have become a benchmark for excellence in plastic machinery.

What Exactly Is a PET Sheet Making Machine?

A PET sheet making machine is an advanced extrusion system that processes polyethylene terephthalate (PET) pellets or flakes into thin, uniform sheets. These sheets are widely used in packaging, electronics, construction, and even the medical field due to their strength, clarity, and recyclability.

The machine takes raw materials through a heating, extrusion, and rolling process—producing consistent, high-quality sheets that meet the rigorous standards of both domestic and international markets.

But not all PET sheet machines are created equal. This is where SIVITE’s decade-long commitment to research and engineering refinement enters the spotlight.

SIVITE’s Edge: Engineering Meets Excellence

SIVITE’s engineering team brings nearly 10 years of hands-on experience to the table. But it’s not just the know-how that matters—it’s the approach. By focusing on automation, precision control, and energy efficiency, SIVITE ensures that their PET sheet making machines don't just perform—they transform manufacturing floors into high-output, low-waste operations.

What sets SIVITE apart is not just innovation but proven performance. With over 1,500 customer success stories spanning more than 80 countries, including major markets like the United States, Brazil, Vietnam, and South Korea, the reliability of their machinery speaks volumes.

Moreover, with more than 20 independently developed invention patents, SIVITE machines are designed to deliver results while anticipating the demands of tomorrow’s markets.

Precision in Every Layer: The Technology Behind the Machine

Every PET sheet making machine designed by SIVITE incorporates a combination of advanced technologies, including:

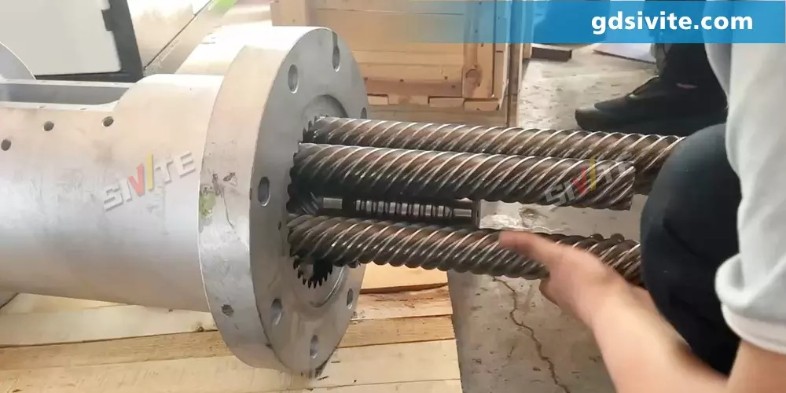

High-performance twin-screw extrusion systems for consistent melt quality

Automatic thickness control to maintain uniformity

Efficient temperature regulation for process stability

Modular configurations allowing tailored solutions for different industries

These features ensure not only the strength and transparency of PET sheets but also support scalability for growing production demands. Add to that the seamless integration of recycling capabilities, and the result is a machine that not only makes products but also reduces material waste and operating costs.

Certified for Global Confidence

Quality certifications aren’t just badges—they’re assurances. SIVITE’s equipment is fully CE-certified and ISO-compliant, affirming its alignment with global safety and quality benchmarks. This offers manufacturers peace of mind when entering or expanding into regulated markets across Europe, North America, and Asia.

Such compliance also speaks to the company’s dedication to long-term partnership—offering not only a machine but a foundation for sustainable growth.

More Than Machinery: A Partner in Progress

Purchasing a PET sheet making machine from SIVITE is not a one-off transaction. It's an entry point into a comprehensive service experience. From pre-sale consultation to installation, training, and after-sales support, the company ensures that every client—regardless of scale—is set up for success.

With a client-first mindset, SIVITE has developed long-term relationships with manufacturers of all sizes. Whether it’s a startup looking to scale production or an industry leader seeking to upgrade their production line, SIVITE delivers tailored advice and responsive support to help navigate every phase of growth.

Global Reach, Local Sensibility

The wide reach of SIVITE’s products—present in over 80 countries—reflects the company's sensitivity to regional demands. Their solutions are built not just to perform, but to adapt to local market requirements, raw material availabilities, and regulatory expectations.

From eco-conscious PLA extrusion for sustainable packaging startups to robust PP sheet production for industrial uses, SIVITE’s machinery is versatile enough to address both mainstream and niche manufacturing needs.

The Real Impact: Efficiency, Cost, and Product Performance

Modern manufacturers don’t just seek output—they want efficiency. SIVITE’s PET sheet making machines are engineered to lower energy consumption while maximizing throughput. This isn’t just a matter of reduced utility bills. It’s about long-term cost reduction, resource optimization, and improved profit margins.

Moreover, the superior design of these machines leads to fewer downtimes, minimal maintenance, and consistent product performance. The result? Higher customer satisfaction, lower operational stress, and a stronger competitive edge.

Looking Ahead: The Future of PET Sheet Production

As global industries place increasing value on sustainability, automation, and precision manufacturing, the role of advanced PET sheet making machines will only continue to grow. Companies that invest in cutting-edge technology today position themselves to lead tomorrow.

SIVITE, with its solid foundation in innovation, customer service, and certified quality, offers more than a solution—it provides a strategic advantage. Whether it’s to reduce material costs, enhance product quality, or future-proof your operations, the right PET sheet making machine can become the backbone of a resilient, forward-thinking manufacturing ecosystem.

The question manufacturers must now ask isn’t whether to upgrade—but how soon they can afford to.