Get familiar with the foundations of SLS 3D printing or selective laser sintering. Learn about Selective SLS 3d printing services, its benefits for quick prototyping and low-production runs, and the materials and customization choices that will work best for your component or project.

A 3D Printing Method that's Both Established and Trustworthy

However, SLS 3d printing services is presently one of the most popular methods of 3D printing. A wide range of applications and use cases show SLS's usefulness in allowing quick prototyping and manufacture of moveable components.

Excellent Mechanical Features

Layer adhesion improves when the powder is fused with a laser beam. SLS 3D printers produce objects and models with isotropic mechanical characteristics. Therefore, better strength, stiffness, and elongation may be achieved using an sls printing services printer. Many engineers continue to depend on SLS 3D printing technology to get long-lasting prints.

3D Printing in Batches

SLS 3D printing streamlines and quickens the process of printing in bulk. A single SLS 3D printer can produce consistent components, simplifying the prototype and production process.

Quick Printing Speed

In addition to these benefits, prototyping relies heavily on SLS printing's rapid turnaround time. By printing numerous components in the same batch, you may fulfil orders from various clients with a single machine run. Prototypes, assuming they are made from the same material. When the price of a production run is divided across multiple items, production time is shortened, and expenses are reduced. SLS well shows this benefit.

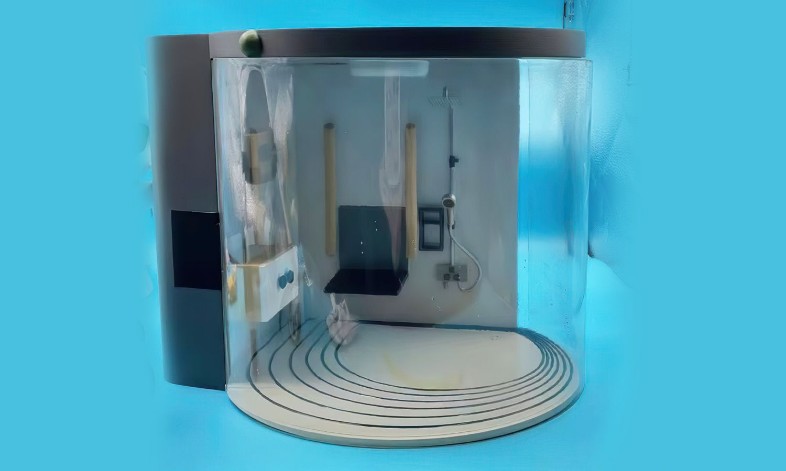

SLS 3D Printing: How Does It Function?

Laser sintering 3D printing (SLS) employs a laser to fuse polymer powder into solid objects. The component's whole cross-section is scanned for accuracy before construction begins. This is how the procedure goes down:

The powder storage section and the construction zone are preheated to a temperature slightly below the polymer's melting point.

The powder on the construction platform is reapplied using a re-coating blade.

The polymer powder particles are then selectively sintered (fused) using a CO2 laser that scans the surface of the subsequent layer.

When a layer is finished, the construction platform descends, and the blade begins re-coating the surface. This procedure is repeated until the whole component is completed.

The printed components are entirely enclosed in unmelted powder after printing. It might take as long as 12 hours for the powder bin to cool down to the point when the components can be unpacked.

What Kinds Of Materials May Be Utilized In SLS Printing?

Polyamide 12, often known as Nylon 12, is the most used SLS material. PA 12 powder costs around $50-$60 per kg. Although PA 11 and PEEK are also examples of engineering plastics, they are less popular. The mechanical and thermal behaviour of the resulting SLS item may be enhanced by adding different additives to polyamide powder. Carbon fibres, glass fibres, and aluminium are all examples of additions. Materials with a high concentration of additives are often more brittle and exhibit significant anisotropy.

What Post-Processing Options Exist For SLS?

The surface of components produced using SLS 3D printing process has a powdery, grainy texture, making them amenable to staining. Media polishing, dying, spray painting, and lacquering are some post-processing techniques that significantly enhance the aesthetic of SLS-produced items. Waterproofing them or plating them with metal may also improve their usefulness.

Conclusion

As one of the most foresightful additive manufacturing technologies, SLS is still a popular choice among engineers. With SLS 3D printing materials, they can make models and components with intricate geometries and try out new shapes.